¶ CAD Design Guidelines

This page serves as a guideline on tolerances and design characteristics used in the OpenAstroTech project. If you make addons or modifications, please follow these.

¶ Screws

Wherever possible, use M3x12 and M4x12mm socket head screws.

¶ Hole diameters

| Screw Size | Self-tapping | Normal (pass thru) | Sunken Head | Heat inserts | Sunken Hex nutwidth/depth |

|---|---|---|---|---|---|

| M3 | 2.9mm | 3.6mm | 6.2mm | 4.4mm (x4.6) | 5.7mm / 2.5mm |

| M4 | 3.9mm | 4.6mm | 7.5mm | 5.8mm (x6) | 7.1mm / 3mm |

| M5 | 5.6mm | 8.8mm | diam-0.2mm | 8.1mm / 4mm | |

| M6 | 6.6mm | 10.6mm | diam-0.2mm |

¶ Chamfers and fillets

Wherever possible, add a 0.5mm chamfer to the bottom and top surface corners for nicer print quality and less pointy parts.

Wherever possible, add R2 fillets to side corners of the part. This improves print quality by not having the printhead move sharp corners.

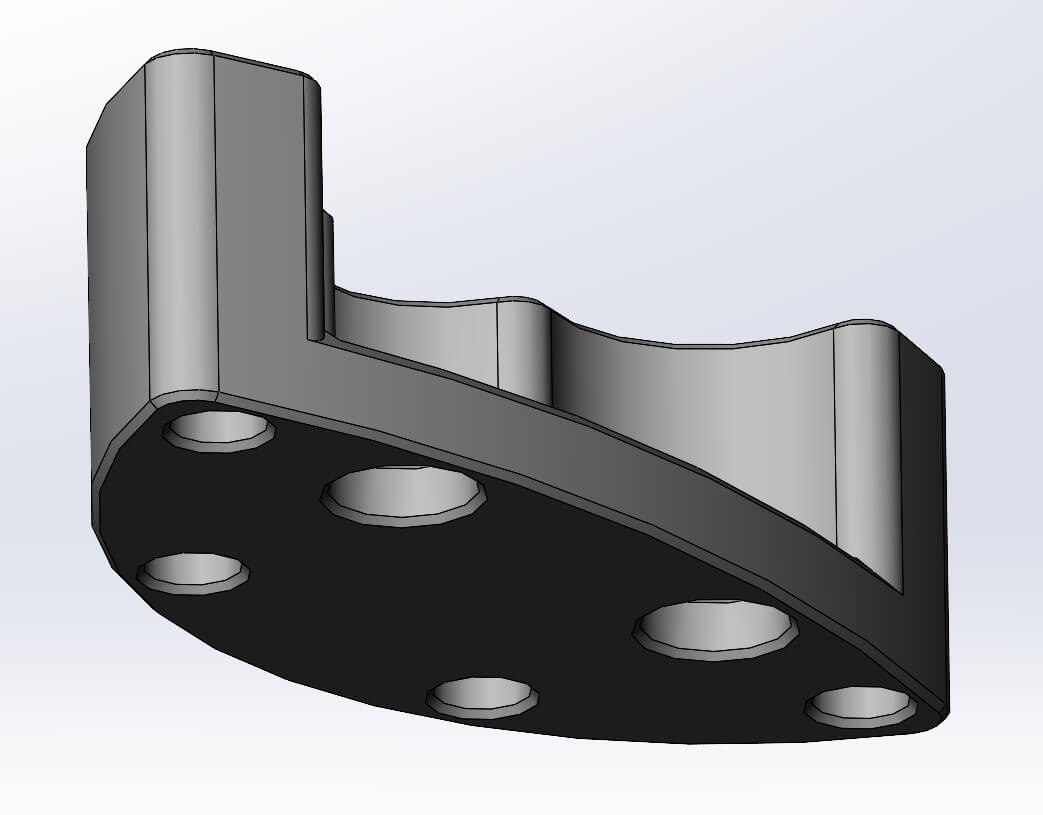

Take this part as an example, the bottom and top surfaces (even the holes) have 0.5mm chamfers and all sharp corners have fillets added.

¶ 2020 Extrusions

¶ TNut attachment

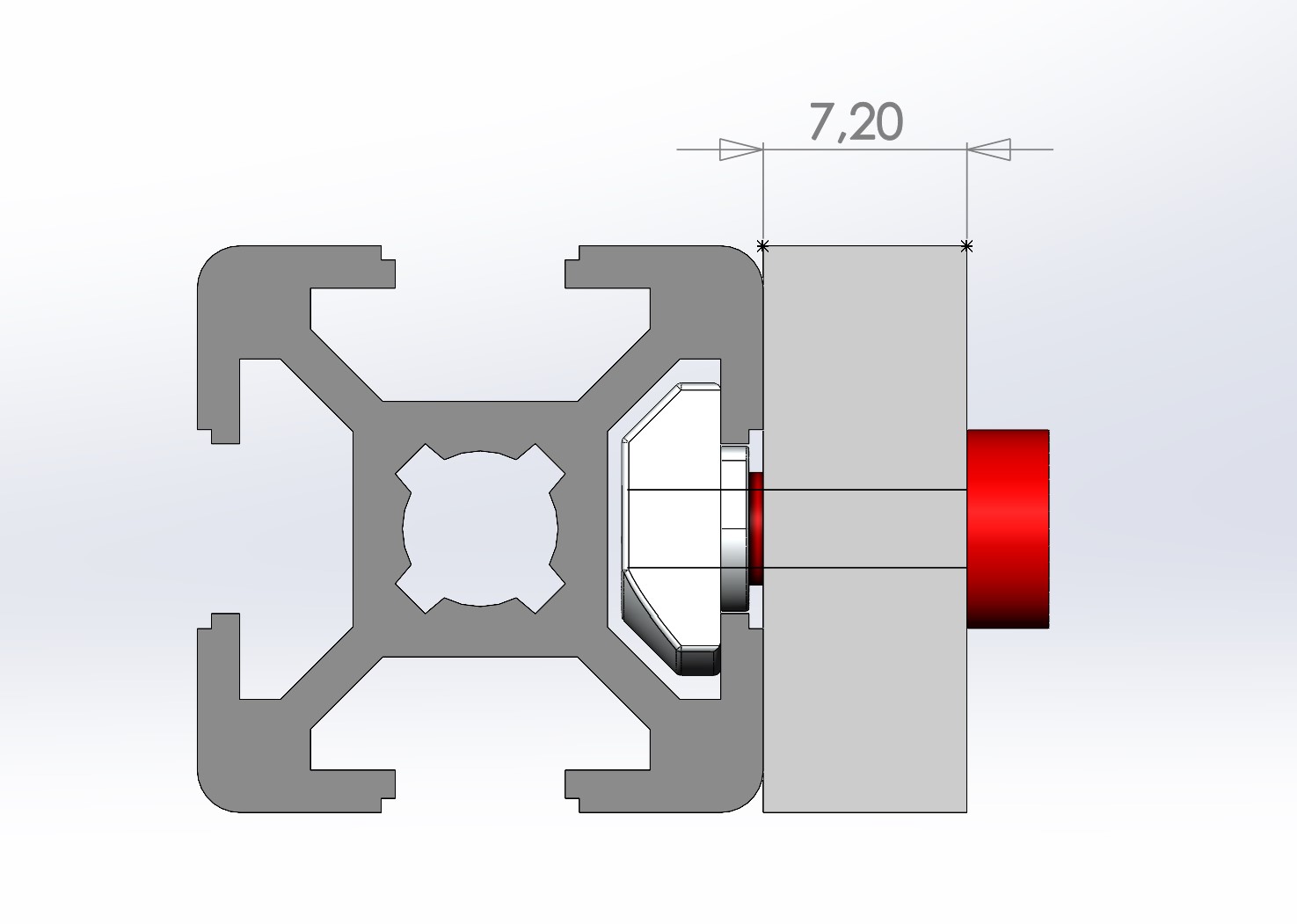

Use M4x12mm screws.

Distance of screwhead to extrusion/part thickness: 7.2mm

¶ Slot Ridge

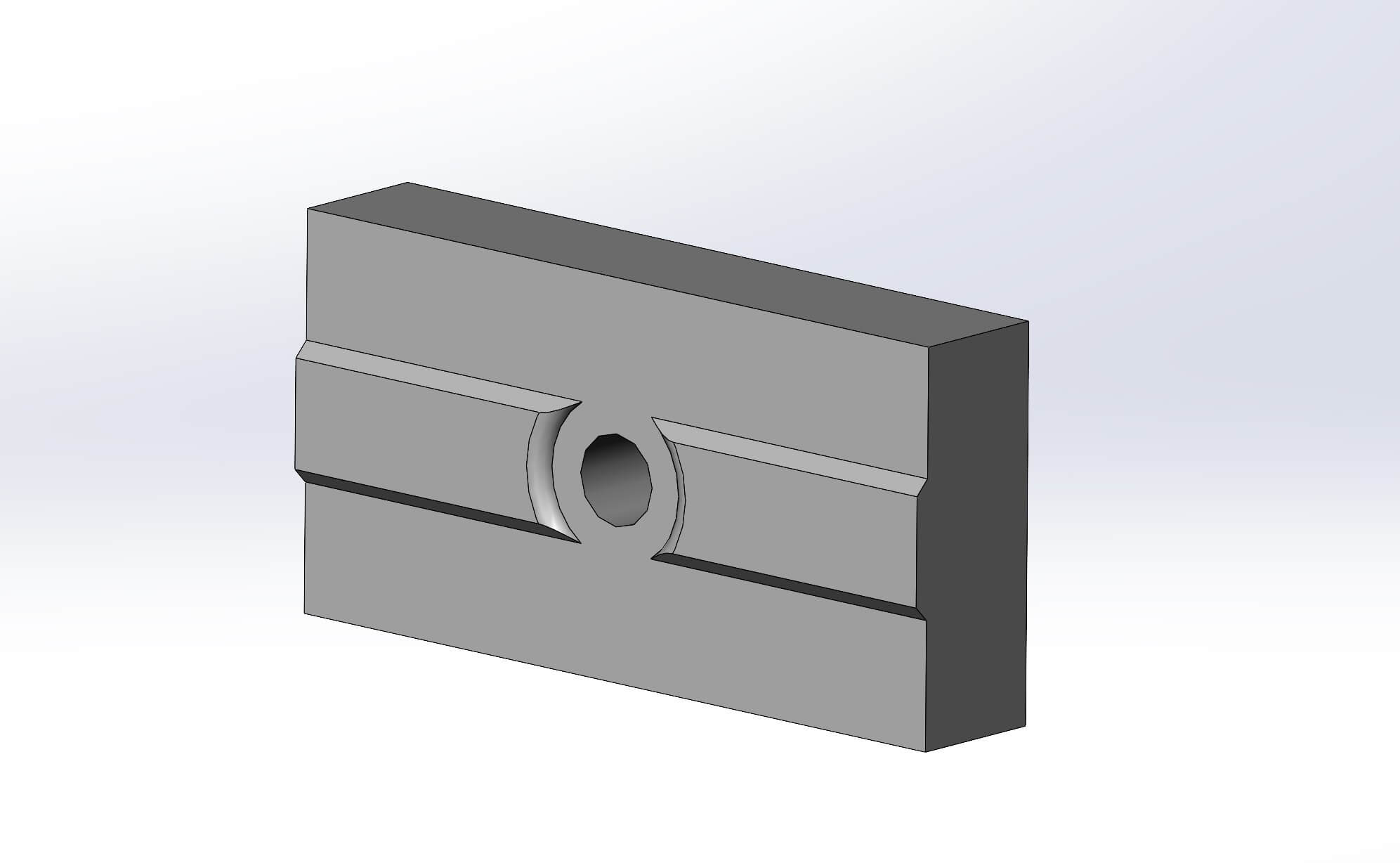

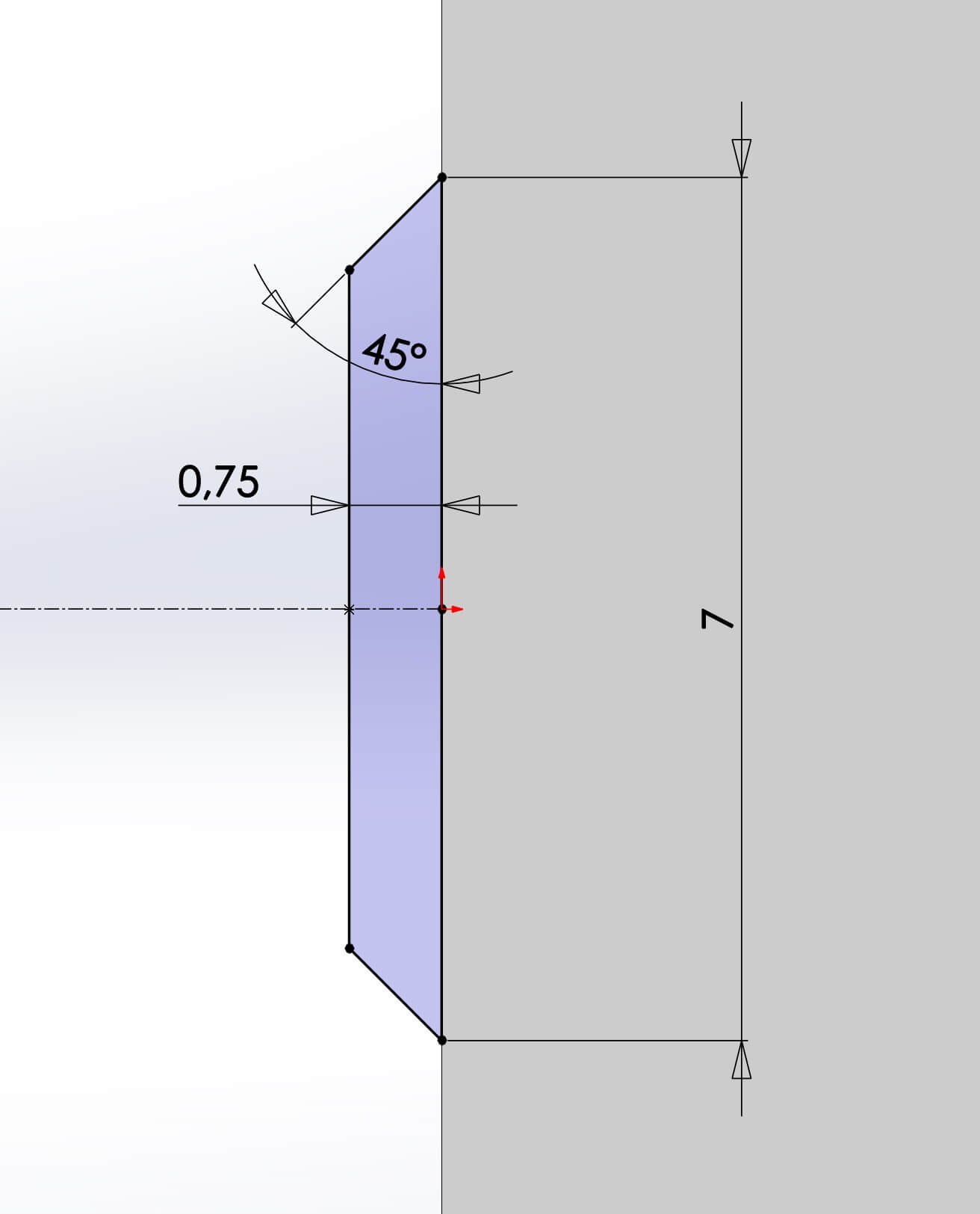

If print orientation and part shape allows, add a ridge on the extrusion side of the part for easier alignment and better strength.

Ridge should have the following dimensions:

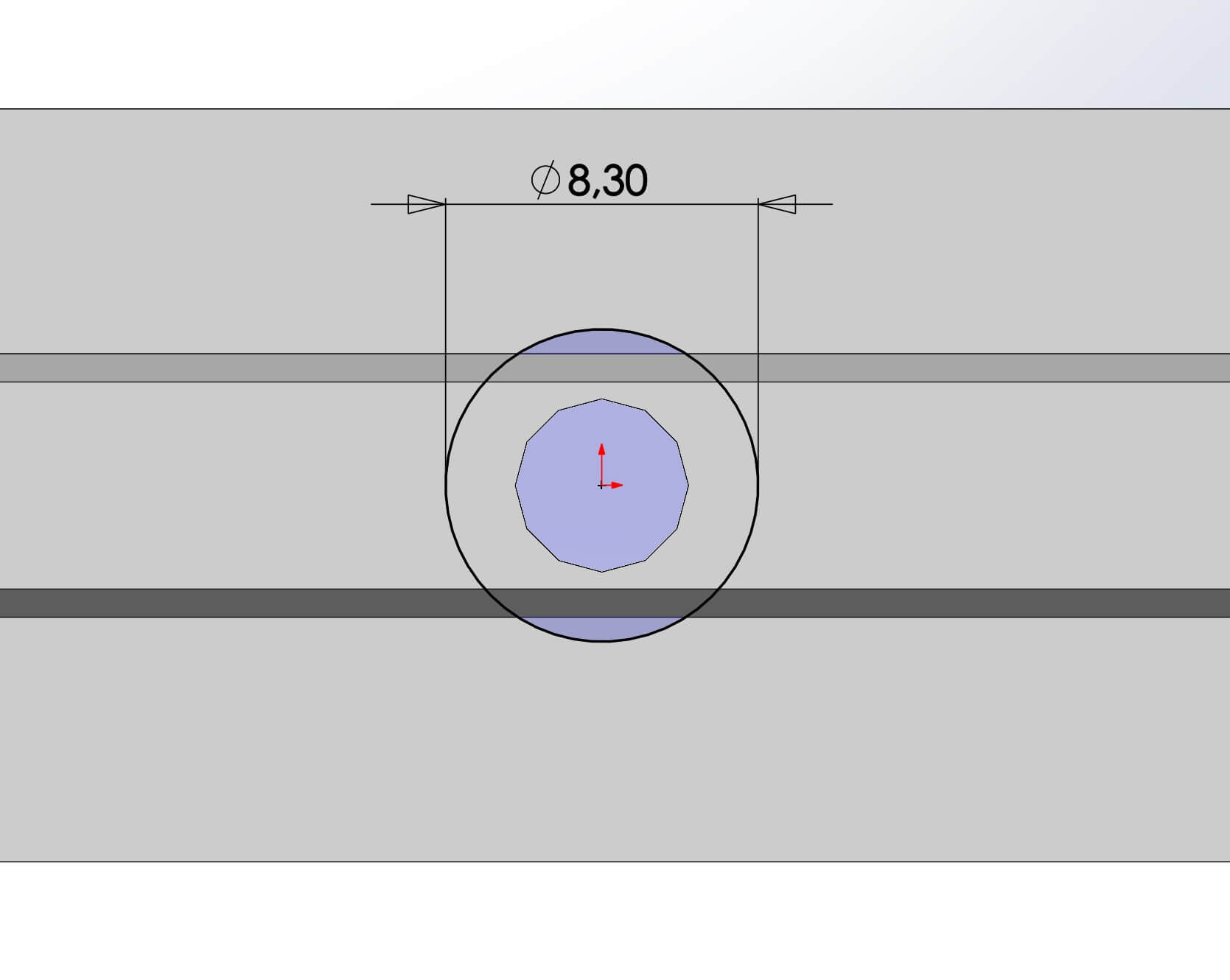

Add a 8.3mm cut over the M4 borehole so the TNut can still turn:

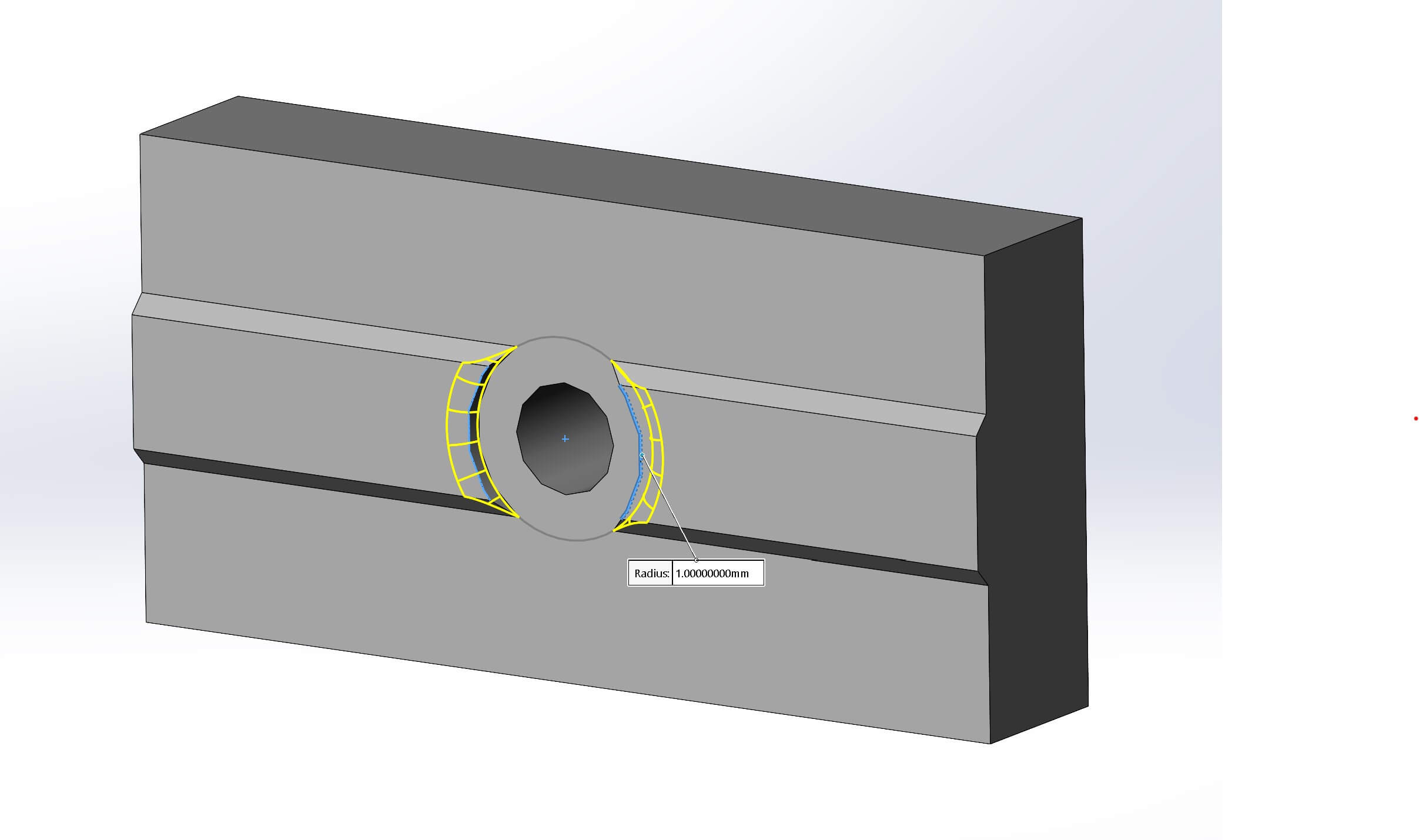

Add R1 fillets for nicer printing: